· By Trevor Horne

What to Know About Steam Sterilizers in Shared Practices

In shared healthcare settings like multi-provider dental offices or group surgical centres, equipment often travels between hands. It’s common for multiple teams to use the same tools, trays, and machines throughout the day. That shared use brings some obvious benefits, but it also comes with risks, especially when it comes to cleaning and sterilization.

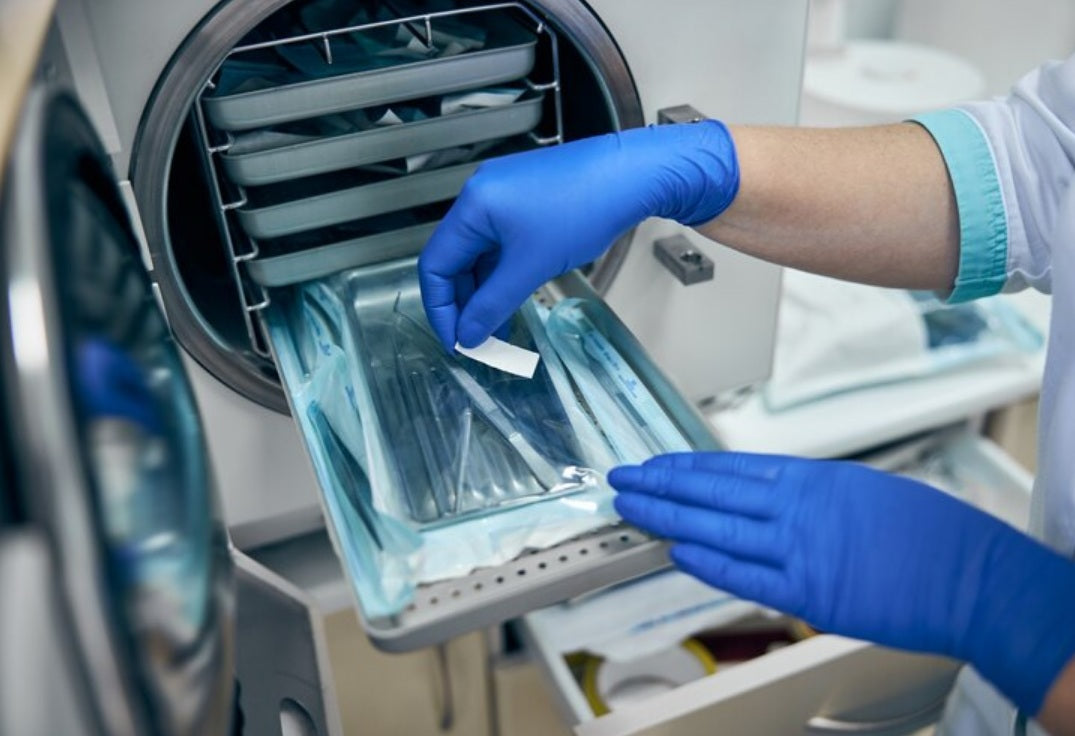

Steam sterilizers play a big part in keeping instruments ready for safe use. These high-pressure machines make it possible to disinfect everything from handheld tools to reusable surgical sets between patients. But when one sterilizer serves several providers or departments, routines need to be tight and consistent. Without clear systems in place, mix-ups happen, and safety can fall through the cracks.

Here’s what we keep in mind when managing steam sterilizers in shared clinics—how they work, where they can break down, and how to keep their use simple, safe, and stress-free even during a fast-paced fall season.

How Steam Sterilizers Work

Steam sterilizers rely on two basic things to get the job done, heat and pressure. These machines work by pushing steam into a sealed chamber, raising the temperature enough to kill bacteria, viruses, and other microbes. It's a quick, reliable way to sanitize instruments between patient uses.

Most tools made from stainless steel and certain polymers are safe to sterilize this way. Items like dental scalers, extraction tools, hemostats, and certain surgical instruments are strong enough to handle the high temperatures. Each cycle is timed and pressurized based on the type of load. A wrapped surgical pack usually runs longer than a few loose items, while porous materials might need a different setting altogether.

In many shared clinics, you’ll find tabletop steam sterilizers. These smaller units fit well in compact sterilization bays and can handle dozens of tools per cycle. In larger facilities or OR-style settings, a floor model autoclave might be in place instead. The key difference is size, though the core function stays the same.

Shared Use: What Needs Extra Attention

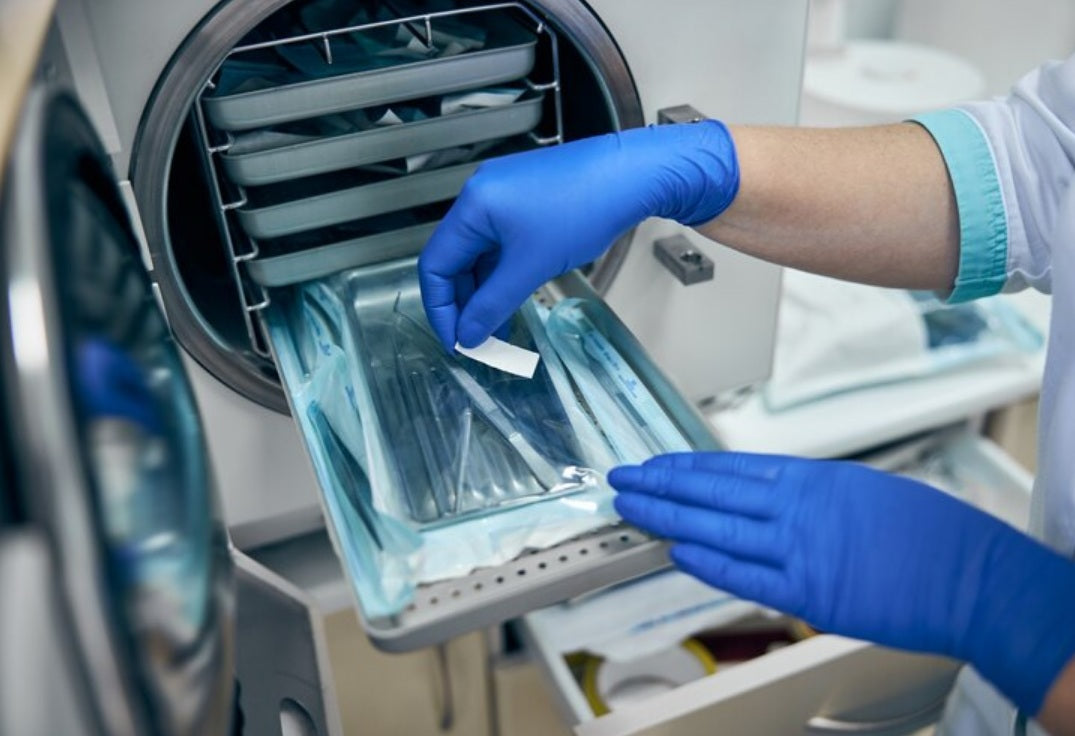

When multiple teams use one machine, a few issues tend to pop up. The first is load tracking. If instruments from two different providers get sterilized together without a clear labelling system, it’s easy for things to get misplaced or left behind.

Cleaning habits can differ too. One team may dry and bag their tools before loading them, while another might leave items damp or skip a visual check. These small differences matter. Inconsistent prep may lead to instruments not fully drying during the cycle or packaging tearing inside the chamber.

That’s why having a clear schedule and shared standards is key. Keep things simple with a few predictable habits:

- Label each tray or wrapped pack with date, time, and initials

- Use a shared logbook or digital tracker for each load

- Mark instruments by department, provider, or room number

- Rotate responsibility for unloading and restocking to keep habits consistent

Regular checks also go a long way. It helps to assign someone weekly to inspect the sterilizer seals or check that filters and drains are clear. By putting these tasks on rotation, the burden doesn’t fall on just one person, and nothing gets missed.

Preventing Misuse and Overuse

Steam sterilizers are heavy-duty machines, but they still need care. When clinics get busy, it’s tempting to load them up or run them back-to-back to keep up with demand. Overloading the chamber or skipping steps in the cleaning process can lead to incomplete sterilization or longer downtime later on.

Running a cycle with too many instruments can restrict steam flow, leaving cold spots in the load. Those cold spots are where microbes might survive. Any reusable tool packed too tightly or placed where steam can’t circulate properly may not get fully sterilized.

To keep the machine in good working shape:

- Don’t fill the chamber beyond its rated load

- Allow a few minutes between cycles to let the chamber cool

- Wipe out moisture after the cycle to keep the chamber dry

- Check door seals weekly for cracks or wear

If staff are unsure who’s in charge of upkeep, it’s easy for little things to get skipped. Assigning one or two people each week to manage routine care can help keep everyone aligned. It’s about building habits, not just assigning blame when something gets missed.

Seasonal Considerations for Fall Clinics

Fall usually feels like a fresh start in many practices. Appointment volumes increase after the summer holidays, and patients tend to catch up on routine care before winter. This uptick in traffic means more instrument use, and that puts extra stress on sterilization setups.

In shared practices, organized equipment can make a difference in how quickly teams turn over rooms and reset for the next case. Make space in the schedule for more frequent chamber cleanings. If the sterilizer runs four or five times in a row, plan a short window once or twice a week to drain and wipe it down between rushes.

Fall is also a good time to retrain or remind everyone of mask and glove handling between loads. Cross-handling packs or tools with worn gloves increases the risk of contamination right when the pace starts to pick up.

Finally, keep in mind how tight treatment room turnover can get during these months. Putting a backup sterilizer in place—if your clinic has room—can bring peace of mind. If not, stagger appointments slightly to give the sterilizer time to complete full cycles without pressure.

Adding a compact, mobile option like the ProAssist Bridge Table can also give staff a clean place to prep or stage trays before loading, which reduces bottlenecks around sterilization stations.

Keeping Steam Sterilization Safe, Simple, and Shared

Managing a steam sterilizer in a shared clinic doesn’t have to feel overwhelming. When routines are predictable and responsibilities rotate, the whole team can rely on the system in place. That means fewer mix-ups, better instrument tracking, and less stress during busy stretches.

It all comes back to clear roles and steady follow-through. With good habits, the sterilizer runs more efficiently, stays in better shape, and supports a safe, organized clinic where patients come first. And during busy seasons like fall, those simple steps matter even more.

Busy season or not, your team deserves equipment that keeps up. Our reliable Steam Sterilizers are built for steady use in shared clinic settings. At ProNorth Medical, we help simplify sterilization so your staff can stay focused on care, not equipment.

- Choosing a selection results in a full page refresh.

- Press the space key then arrow keys to make a selection.

Your cart -

Your cart is currently empty.